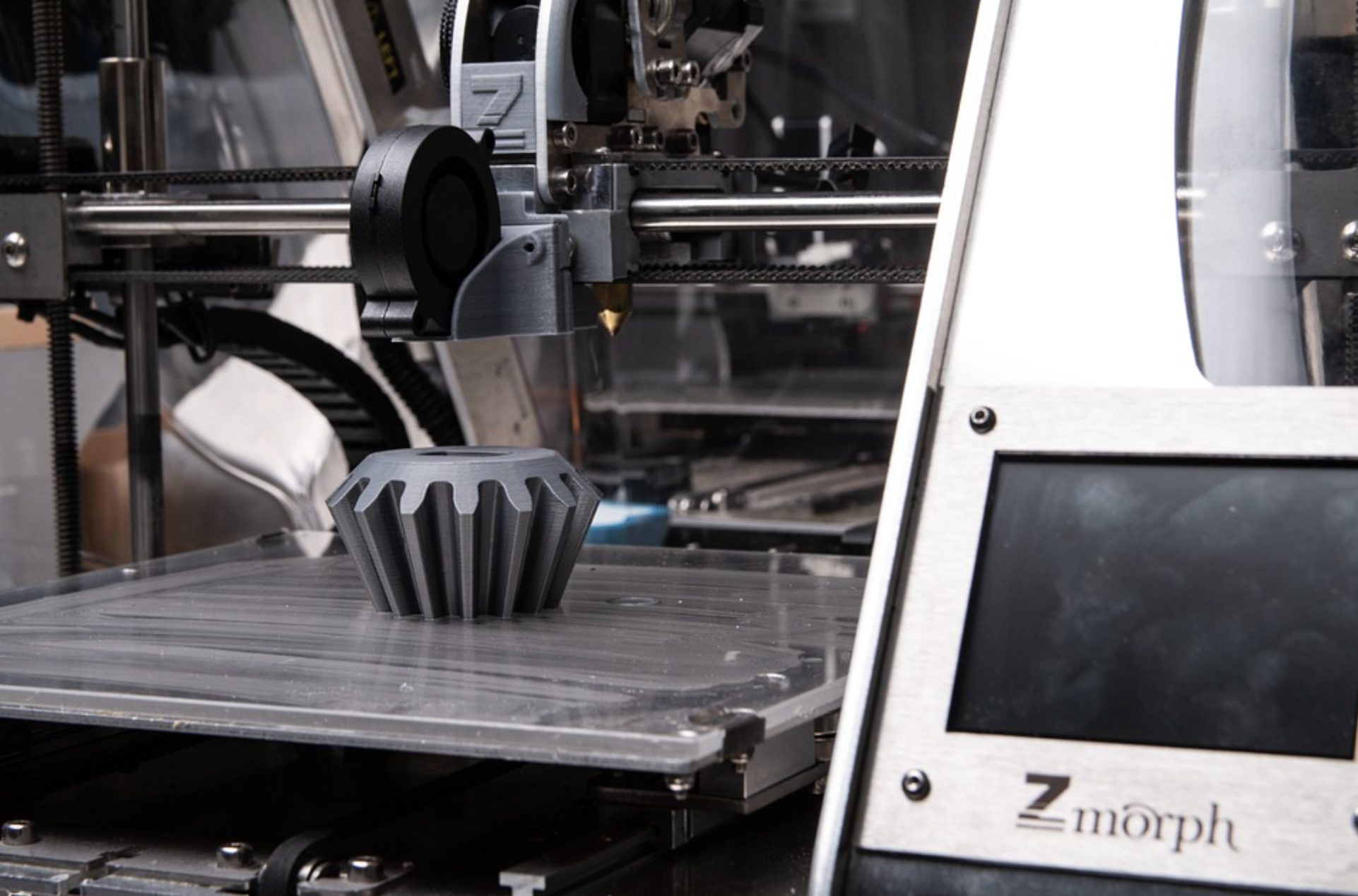

[객원 에디터 4기 / 한동민 기자] 3D printing technology has been developing rapidly, and its potential application in the future cannot be underestimated. However, there is currently a flaw shared by almost all 3D printers: speed. The processing speed of modern 3D printers is very low, making it difficult to produce products in limited-time settings.

3D printing has revolutionized many fields and continues to do so. A multi-photon lithography technique allows the creation of products on a nanoscale by exposing the resin to a series of focused high-intensity laser pulses, which in turn causes the resin at the focal point to solidify almost instantly, thereby allowing 3D shapes to be built.

Although multi-photon lithography has great potential to become a leading technology, it also slows down the 3D printer in creating nano-scaled products. As a graduate researcher at Purdue University, Paul Somers, noted, “multi-photon lithography has been studied for more than 20 years. It has great potential, but it’s still slow. Our goal is to speed it up and scale it up so that it can be used to manufacture useful structures with high speed and high fidelity.”

To speed up multi-photon lithography, a research team at Purdue university used spatiotemporal focusing to print products instantly by separating the laser into multiple wavelengths of light and then recombining them, accurately pinpointing the area of the resin they want to solidify. In doing so, they were able to create a more accurate and immediate printing system. Somers continued, “our technique is continuous. The platform doesn’t stop and start; it moves continuously, so rather than distinct layers, it’s one smooth shape all the way up. This allows us to print much faster, with no layering artifacts, and make complex shapes that traditional 3D printing can’t do.”

Multi-photon lithography and its applications can enable researchers to process direct laser writing, which offers high spatial resolution and gives us insight into the true 3D micro/ nano-structures of devices. Furthermore, its application is continuing to expand, impacting fields including the bioindustry and micromechanics. As this technology develops, its application will be sure to bring human technology to an unprecedented level.

Sources: Purdue Engineering, Science Direct